At J&R, quality is our

priority

We commit to continually improve our Quality Management System by establishing quality objectives, addressing risks and opportunities and promoting ethical behavior.

Learn about the technology that powers J&R

Quality and Metrology

We're alwys and the lookout to improve the prescision and the speed at which we're able to inspect the parts we machined. A few of our technologies include:

- Hexagon Metrology Multi-Axis DCC CMM with Temprature Comensation

- George Products Vision Inspection System

- Trimos Digital Height Gage

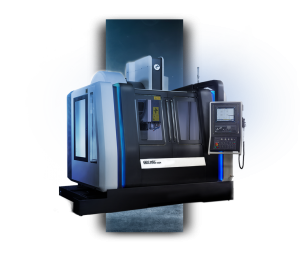

Machines

Just like our Quality department, our machine shop is always looking for the ultimate edge when it comes to mills and lathes. It's why our shop is equipped with cutting edge 5-axis mills and 7-axis turn-mills. Limiting the amount of operations we need to perform to machine a part is a valueable cost savings that we can pass on to our customers.

- 1 X 5X-12 | 5-Axis Mill with 12" table, glass scales and 40-tool holder

- 2 X 5X-8 | 5-Axis Mill with 12" table, glass scales and 24-tool holder

- 2 X VFM-4024 | 4-Axis Mill

- 2 X Cyclone-32CS | 7-Axis Turn-Mills

- and more!

Programming

Whether it's a blueprint or a solid model, and sometimes even less, we can make a part out of it. We've partnered with Gibbs and use their powerful GibbsCam to get our machines running fast and accurately.

Check out our featured article from 3D Systems: